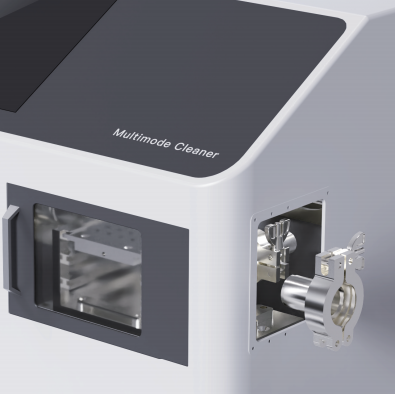

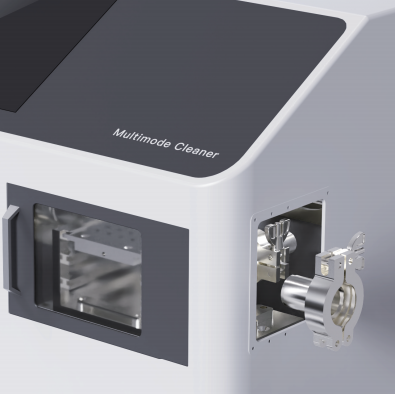

Multi-functional Cleaner MC-4

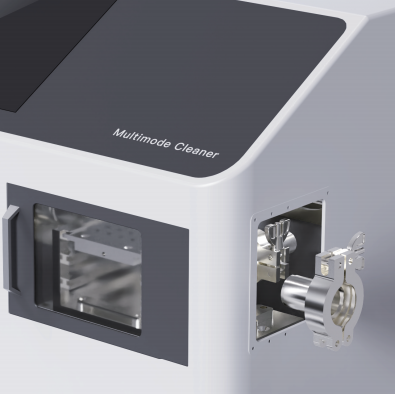

The MC-4 multi-modular Cleaner integrates three cleaning modes: Downstream plasma, UV irradiation, and heating vacuuming desorption. It is suitable for cleaning samples for various SEM, FIB, and TEM.

Classification:

Accessories/Auxiliary Equipment

Core advantages

|

|

User Interface

- 产品描述

- 用户界面

- 性能参数

- 应用案例

-

- Commodity name: Multi-functional Cleaner MC-4

The MC-4 multi-modular Cleaner integrates three cleaning modes: Downstream plasma, UV irradiation, and heating vacuuming desorption. It is suitable for cleaning samples for various SEM, FIB, and TEM.

- Integrate three cleaning modes: Downstream plasma, UV irradiation, and heated vacuum desorption, and can be switched at any time

- Suitable for cleaning various scanning electron microscopes, focused ion beam microscopes, and transmission electron microscope samples

- High-resolution touch screen operation, supports remote control in WiFi environment

- Can be used as a constant temperature vacuum sample storage cabinet

- Special design is adopted to achieve efficient cleaning of samples from scanning electron microscopes and transmission electron microscopes.

- A dedicated port for installing adapter for TEM specimen rod.

- Customizable rod pump storage function.

-

- Intuitive graphical user interface, ease of use.

- Critical process parameters displayed during running, fully controllable throughout the process.

- Modular design, quick switching between different cleaning modules from UI panel.

- Easy maintenance, no special maintenance required.

-

OVERALL PARAMETERS OF THE INSTRUMENT Size of equipment (L*W*H) 470*345*340mm Weight 30kg Size of the sample chamber (L*W*H) 120*120*150mm Size of the touch screen 9inch WORKING PARAMETERS OF HEATING CLEANING Maximum heating temperature 150℃ Temperature control accuracy 1℃ Heating power 130W WORKING PARAMETERS OF CLEANING Radiation power 35W Operating vacuum 5*104Pa WORKING PARAMETERS OF PLASMA CLEANING Cleaning power 5-100W Operating vacuum <80Pa RF frequency 13.56MHz Characteristic resistance 50Ω -

1. Plasma cleaning

- Inductively Coupled Plasma (ICP) technology to generates plasma with much higher particle density than traditional capacitively coupled technology.

- The high concentration of oxygen radicals generated can efficiently remove surface hydrocarbon contaminants on the samples.

- "Downstream" cleaning approach has no damage to the sample and preserves original surface morphology.

Gold particle standards

Before : There is obvious carbon deposit in the central area

After : the carbon deposits are cleaned

2. UV cleaning

- Two wavelength (185nm and 254nm) of UV lights simultaneously irradiate the sample chamber where oxygen is leaked in.

- High concentration, highly active oxygen radicals are generated in the sample chamber.

- Surface hydrocarbon (buildup) reacts with oxygen radicals to decompose into smaller species, then being pumped away.

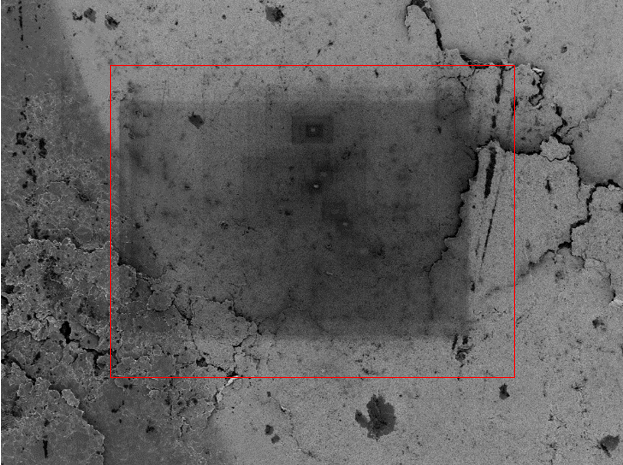

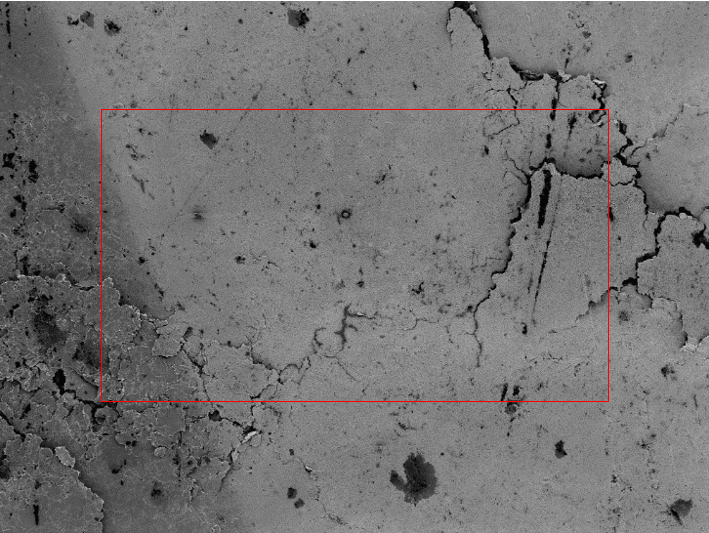

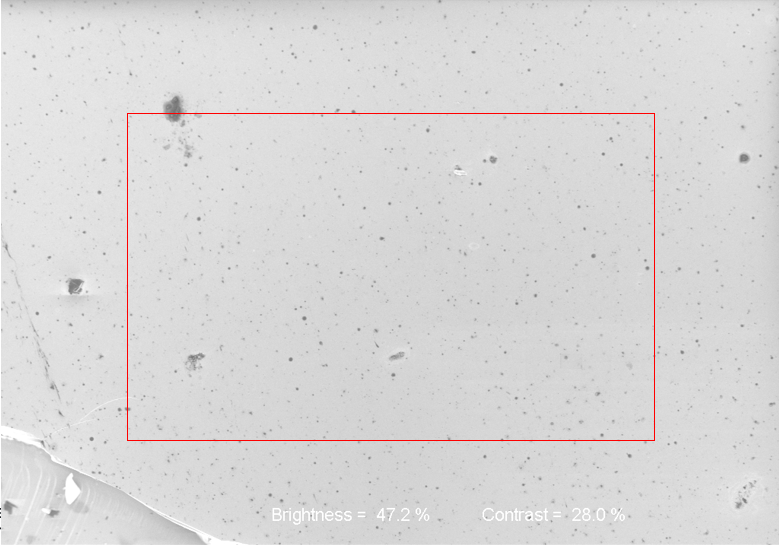

Silicon wafer sample

Before : There is obvious carbon deposit in the central area After : the carbon deposits are cleaned 3. Heating-vacuuming cleaning

- The sample chamber can be heated quickly, up to 150℃ undervacuum so that adsorbed hydrocarbon species can be removed by desorption.

- High-precision temperature control with accuracy within ±1℃.

- Chamber vacuum can be configured at low vacuum mode (10-2 Torr) or high vacuum mode (10- 5 Torr) for different desorption requirement.

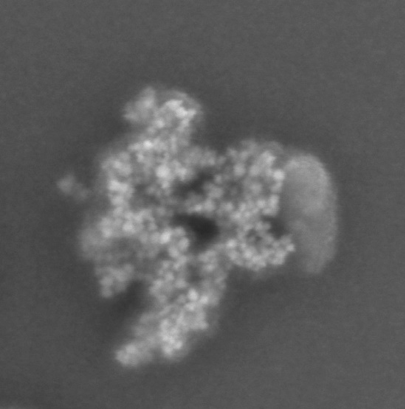

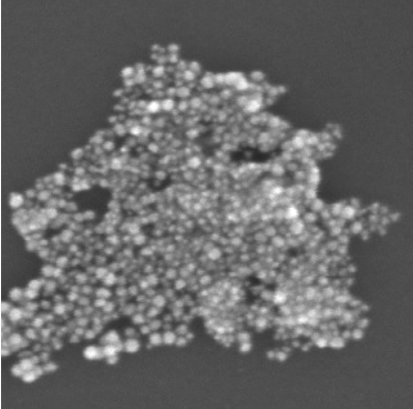

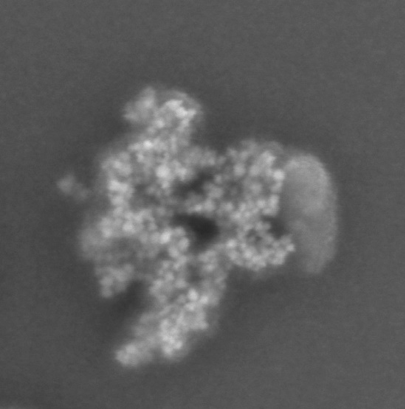

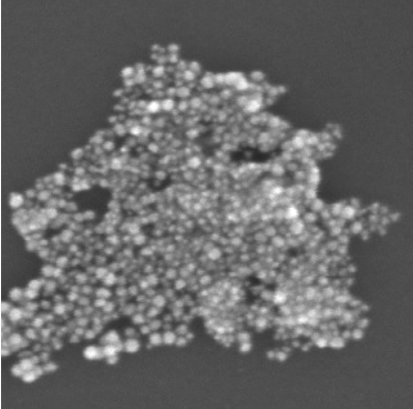

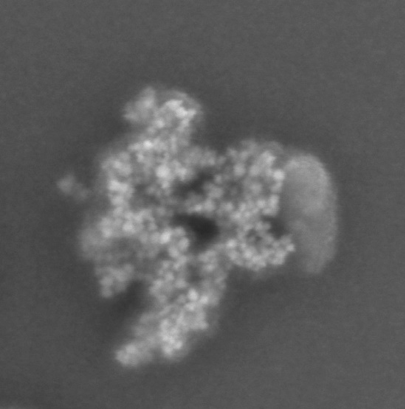

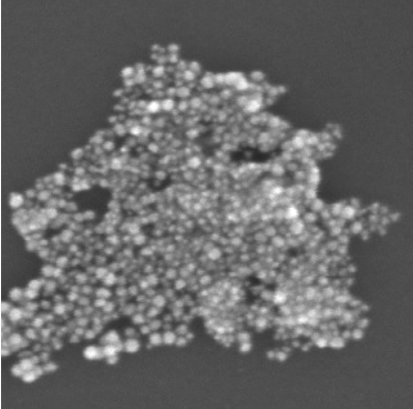

Iron-platinum nanoparticle sample (organic solvent ultrasonic dispersion treatment)

Before cleaning, organic solvent is wrapped around the particles, and the boundaries are blurred during imaging. After cleaning, the organic solvent around the particles is removed, and the imaging clarity is significantly improved.

Performance parameters

- 产品描述

- 用户界面

- 性能参数

- 应用案例

-

- Commodity name: Multi-functional Cleaner MC-4

The MC-4 multi-modular Cleaner integrates three cleaning modes: Downstream plasma, UV irradiation, and heating vacuuming desorption. It is suitable for cleaning samples for various SEM, FIB, and TEM.

- Integrate three cleaning modes: Downstream plasma, UV irradiation, and heated vacuum desorption, and can be switched at any time

- Suitable for cleaning various scanning electron microscopes, focused ion beam microscopes, and transmission electron microscope samples

- High-resolution touch screen operation, supports remote control in WiFi environment

- Can be used as a constant temperature vacuum sample storage cabinet

- Special design is adopted to achieve efficient cleaning of samples from scanning electron microscopes and transmission electron microscopes.

- A dedicated port for installing adapter for TEM specimen rod.

- Customizable rod pump storage function.

-

- Intuitive graphical user interface, ease of use.

- Critical process parameters displayed during running, fully controllable throughout the process.

- Modular design, quick switching between different cleaning modules from UI panel.

- Easy maintenance, no special maintenance required.

-

OVERALL PARAMETERS OF THE INSTRUMENT Size of equipment (L*W*H) 470*345*340mm Weight 30kg Size of the sample chamber (L*W*H) 120*120*150mm Size of the touch screen 9inch WORKING PARAMETERS OF HEATING CLEANING Maximum heating temperature 150℃ Temperature control accuracy 1℃ Heating power 130W WORKING PARAMETERS OF CLEANING Radiation power 35W Operating vacuum 5*104Pa WORKING PARAMETERS OF PLASMA CLEANING Cleaning power 5-100W Operating vacuum <80Pa RF frequency 13.56MHz Characteristic resistance 50Ω -

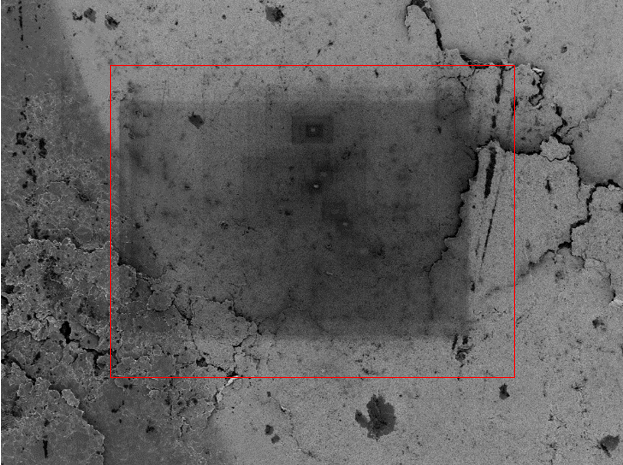

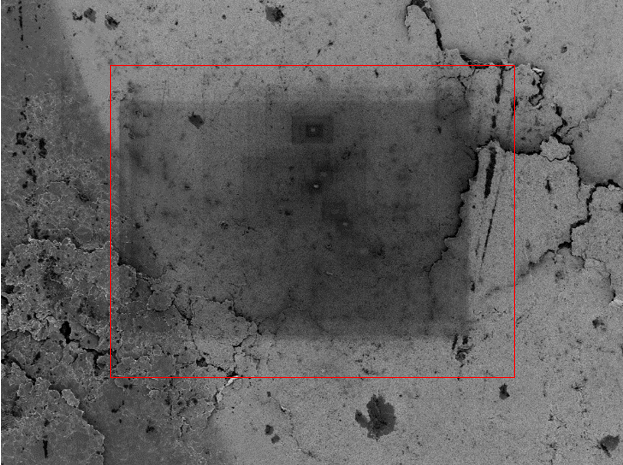

1. Plasma cleaning

- Inductively Coupled Plasma (ICP) technology to generates plasma with much higher particle density than traditional capacitively coupled technology.

- The high concentration of oxygen radicals generated can efficiently remove surface hydrocarbon contaminants on the samples.

- "Downstream" cleaning approach has no damage to the sample and preserves original surface morphology.

Gold particle standards

Before : There is obvious carbon deposit in the central area

After : the carbon deposits are cleaned

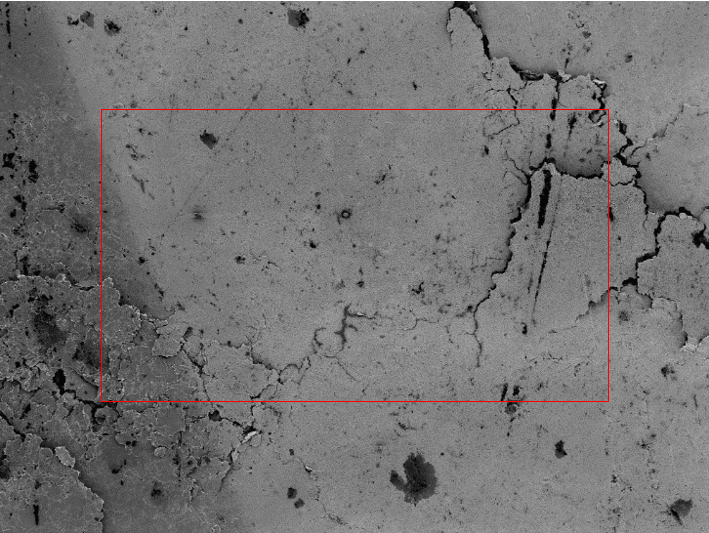

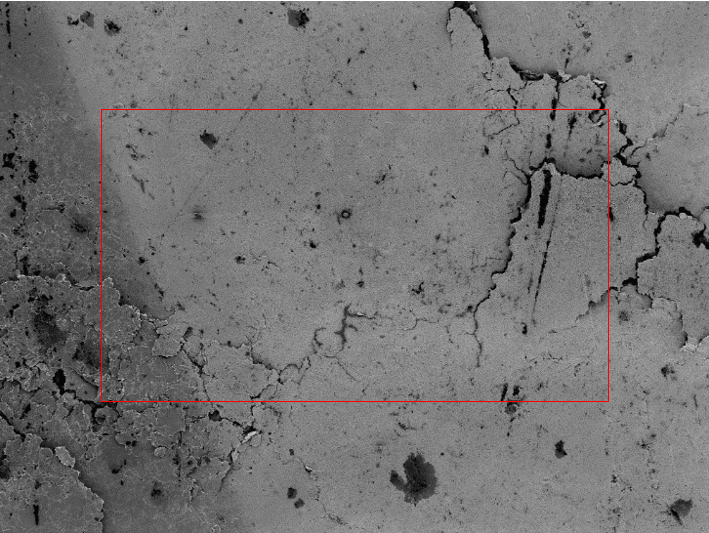

2. UV cleaning

- Two wavelength (185nm and 254nm) of UV lights simultaneously irradiate the sample chamber where oxygen is leaked in.

- High concentration, highly active oxygen radicals are generated in the sample chamber.

- Surface hydrocarbon (buildup) reacts with oxygen radicals to decompose into smaller species, then being pumped away.

Silicon wafer sample

Before : There is obvious carbon deposit in the central area After : the carbon deposits are cleaned 3. Heating-vacuuming cleaning

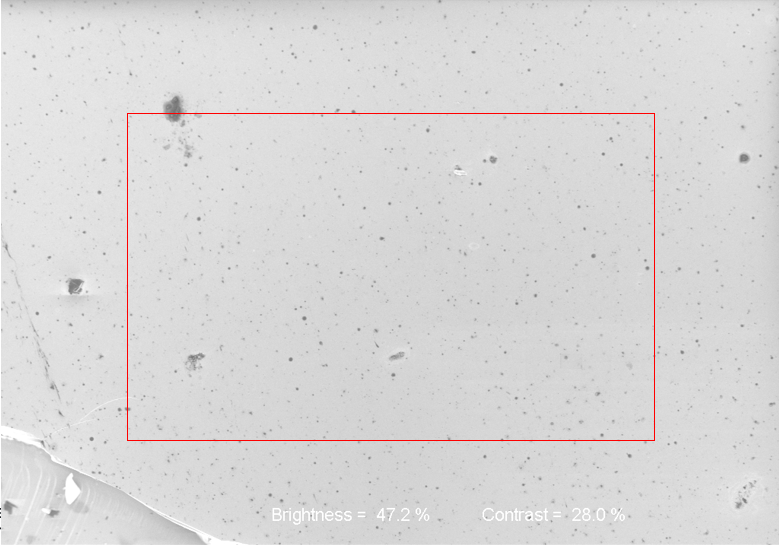

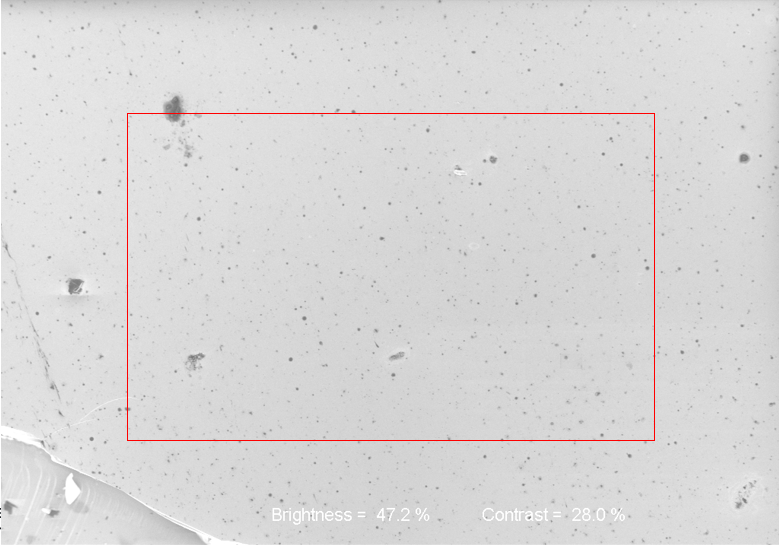

- The sample chamber can be heated quickly, up to 150℃ undervacuum so that adsorbed hydrocarbon species can be removed by desorption.

- High-precision temperature control with accuracy within ±1℃.

- Chamber vacuum can be configured at low vacuum mode (10-2 Torr) or high vacuum mode (10- 5 Torr) for different desorption requirement.

Iron-platinum nanoparticle sample (organic solvent ultrasonic dispersion treatment)

Before cleaning, organic solvent is wrapped around the particles, and the boundaries are blurred during imaging. After cleaning, the organic solvent around the particles is removed, and the imaging clarity is significantly improved.

Application Cases

- 产品描述

- 用户界面

- 性能参数

- 应用案例

-

- Commodity name: Multi-functional Cleaner MC-4

The MC-4 multi-modular Cleaner integrates three cleaning modes: Downstream plasma, UV irradiation, and heating vacuuming desorption. It is suitable for cleaning samples for various SEM, FIB, and TEM.

- Integrate three cleaning modes: Downstream plasma, UV irradiation, and heated vacuum desorption, and can be switched at any time

- Suitable for cleaning various scanning electron microscopes, focused ion beam microscopes, and transmission electron microscope samples

- High-resolution touch screen operation, supports remote control in WiFi environment

- Can be used as a constant temperature vacuum sample storage cabinet

- Special design is adopted to achieve efficient cleaning of samples from scanning electron microscopes and transmission electron microscopes.

- A dedicated port for installing adapter for TEM specimen rod.

- Customizable rod pump storage function.

-

- Intuitive graphical user interface, ease of use.

- Critical process parameters displayed during running, fully controllable throughout the process.

- Modular design, quick switching between different cleaning modules from UI panel.

- Easy maintenance, no special maintenance required.

-

OVERALL PARAMETERS OF THE INSTRUMENT Size of equipment (L*W*H) 470*345*340mm Weight 30kg Size of the sample chamber (L*W*H) 120*120*150mm Size of the touch screen 9inch WORKING PARAMETERS OF HEATING CLEANING Maximum heating temperature 150℃ Temperature control accuracy 1℃ Heating power 130W WORKING PARAMETERS OF CLEANING Radiation power 35W Operating vacuum 5*104Pa WORKING PARAMETERS OF PLASMA CLEANING Cleaning power 5-100W Operating vacuum <80Pa RF frequency 13.56MHz Characteristic resistance 50Ω -

1. Plasma cleaning

- Inductively Coupled Plasma (ICP) technology to generates plasma with much higher particle density than traditional capacitively coupled technology.

- The high concentration of oxygen radicals generated can efficiently remove surface hydrocarbon contaminants on the samples.

- "Downstream" cleaning approach has no damage to the sample and preserves original surface morphology.

Gold particle standards

Before : There is obvious carbon deposit in the central area

After : the carbon deposits are cleaned

2. UV cleaning

- Two wavelength (185nm and 254nm) of UV lights simultaneously irradiate the sample chamber where oxygen is leaked in.

- High concentration, highly active oxygen radicals are generated in the sample chamber.

- Surface hydrocarbon (buildup) reacts with oxygen radicals to decompose into smaller species, then being pumped away.

Silicon wafer sample

Before : There is obvious carbon deposit in the central area After : the carbon deposits are cleaned 3. Heating-vacuuming cleaning

- The sample chamber can be heated quickly, up to 150℃ undervacuum so that adsorbed hydrocarbon species can be removed by desorption.

- High-precision temperature control with accuracy within ±1℃.

- Chamber vacuum can be configured at low vacuum mode (10-2 Torr) or high vacuum mode (10- 5 Torr) for different desorption requirement.

Iron-platinum nanoparticle sample (organic solvent ultrasonic dispersion treatment)

Before cleaning, organic solvent is wrapped around the particles, and the boundaries are blurred during imaging. After cleaning, the organic solvent around the particles is removed, and the imaging clarity is significantly improved.