Micro-Gas injection system Dalex-100

The gas injection system (GIS) is one of the basic configurations of FIB-SEM. It plays two very important roles in FIB-SEM, one is the material deposition function, and the other is the auxiliary etching function. The Dalex-100 gas injection system provides Pt, W and C for deposition protection during cross-section and TEM sample preparation, Pt, W and SiO2 for circuit repair, and to improve Si cutting Rate of XeF2. In addition, it can provide other special precursor gases for milling or gas dry etching of certain materials.

Classification:

Accessories/Auxiliary Equipment

Core advantages

CORE ADVANTAGES:

- Compact design, small size, compatible with various scanning electron microscopes/ focused ion beam microscopes.

- Micro-fine needle can accurately deliver precursor gas to the target processing position.

- Can be equipped with three different types of gas sources, such as metal (tungsten, platinum), insulator (silicon oxide) and etching gas (xenon fluoride).

- Working pressure range can be adjusted to different vacuum applications.

- Can be configured with nitrogen, oxygen, and other gases for pipeline cleaning to reduce contamination.

- User-friendly interface, easy to maintain.

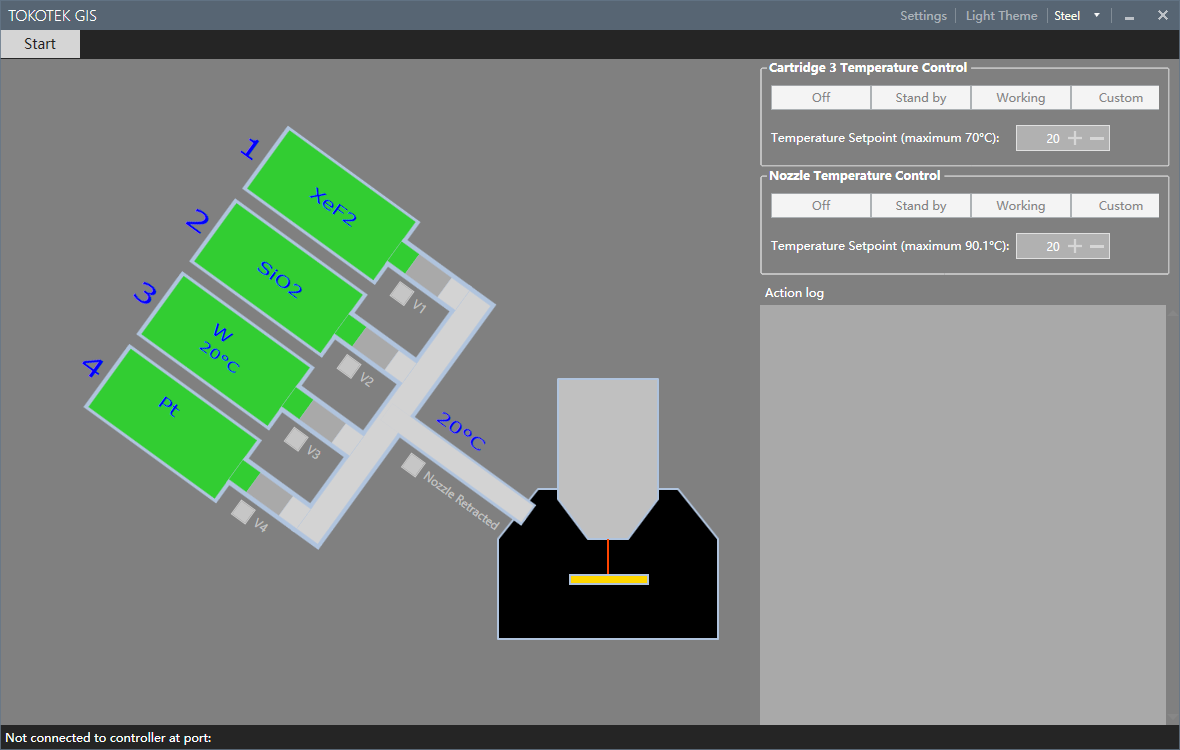

User Interface

- 产品描述

- 用户界面

- 性能参数

- 应用案例

-

- Commodity name: Micro-Gas injection system Dalex-100

The gas injection system (GIS) is one of the basic configurations of FIB-SEM. It plays two very important roles in FIB-SEM, one is the material deposition function, and the other is the auxiliary etching function. The Dalex-100 gas injection system provides Pt, W and C for deposition protection during cross-section and TEM sample preparation, Pt, W and SiO<sub>2</sub> for circuit repair, and to improve Si cutting Rate of XeF<sub>2</sub>. In addition, it can provide other special precursor gases for milling or gas dry etching of certain materials.

CORE ADVANTAGES:

- Compact design, small size, compatible with various scanning electron microscopes/ focused ion beam microscopes.

- Micro-fine needle can accurately deliver precursor gas to the target processing position.

- Can be equipped with three different types of gas sources, such as metal (tungsten, platinum), insulator (silicon oxide) and etching gas (xenon fluoride).

- Working pressure range can be adjusted to different vacuum applications.

- Can be configured with nitrogen, oxygen, and other gases for pipeline cleaning to reduce contamination.

- User-friendly interface, easy to maintain.

-

-

MICRO-GAS-INJECTION SYSTEM PERFORMANCE PARAMETERS Inside diameter of nozzle <500μm Maximum extension distance of needle working 25mm Planar movement range of needle ±2mm Repeat positioning accuracy of needle XYZ axis Better than 5μm Pressure range 10-7mbar~10-5mbar Deposition rate Maximum 150nm/min

(depending on gas type and working pressure)

Overall weight 3.2kg -

Tungsten nanowires deposited on the surface of silicon wafer.

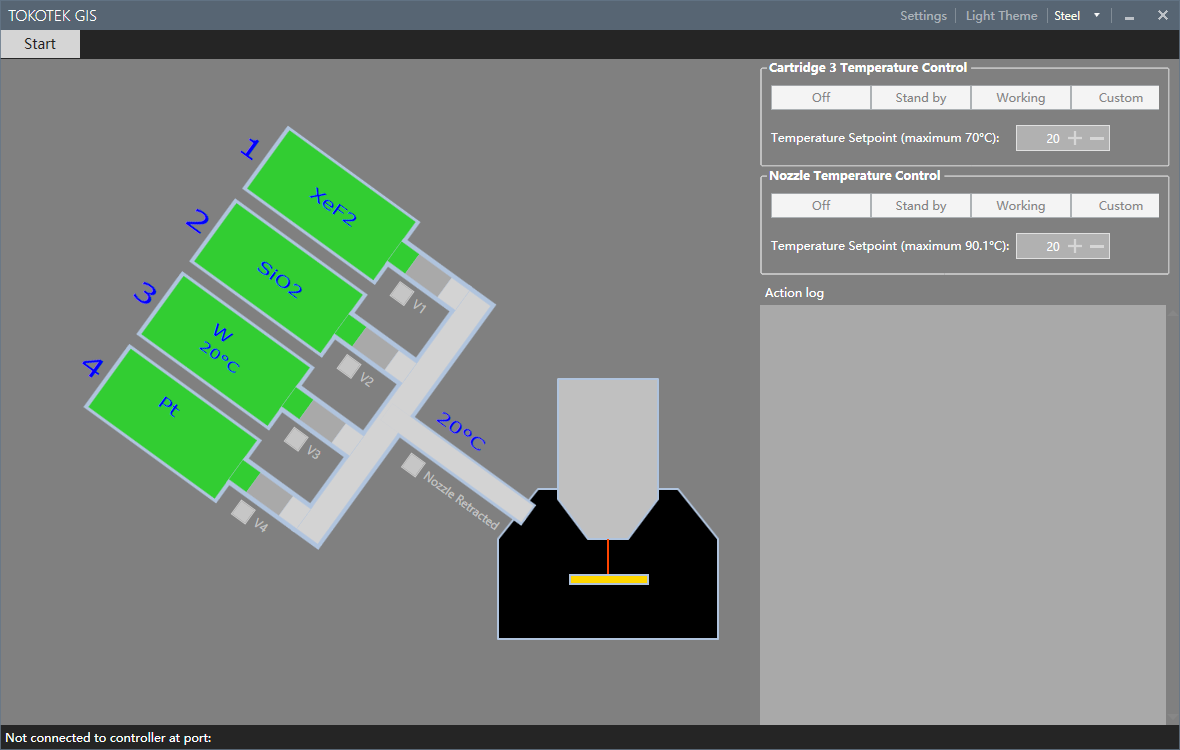

Performance parameters

- 产品描述

- 用户界面

- 性能参数

- 应用案例

-

- Commodity name: Micro-Gas injection system Dalex-100

The gas injection system (GIS) is one of the basic configurations of FIB-SEM. It plays two very important roles in FIB-SEM, one is the material deposition function, and the other is the auxiliary etching function. The Dalex-100 gas injection system provides Pt, W and C for deposition protection during cross-section and TEM sample preparation, Pt, W and SiO<sub>2</sub> for circuit repair, and to improve Si cutting Rate of XeF<sub>2</sub>. In addition, it can provide other special precursor gases for milling or gas dry etching of certain materials.

CORE ADVANTAGES:

- Compact design, small size, compatible with various scanning electron microscopes/ focused ion beam microscopes.

- Micro-fine needle can accurately deliver precursor gas to the target processing position.

- Can be equipped with three different types of gas sources, such as metal (tungsten, platinum), insulator (silicon oxide) and etching gas (xenon fluoride).

- Working pressure range can be adjusted to different vacuum applications.

- Can be configured with nitrogen, oxygen, and other gases for pipeline cleaning to reduce contamination.

- User-friendly interface, easy to maintain.

-

-

MICRO-GAS-INJECTION SYSTEM PERFORMANCE PARAMETERS Inside diameter of nozzle <500μm Maximum extension distance of needle working 25mm Planar movement range of needle ±2mm Repeat positioning accuracy of needle XYZ axis Better than 5μm Pressure range 10-7mbar~10-5mbar Deposition rate Maximum 150nm/min

(depending on gas type and working pressure)

Overall weight 3.2kg -

Tungsten nanowires deposited on the surface of silicon wafer.

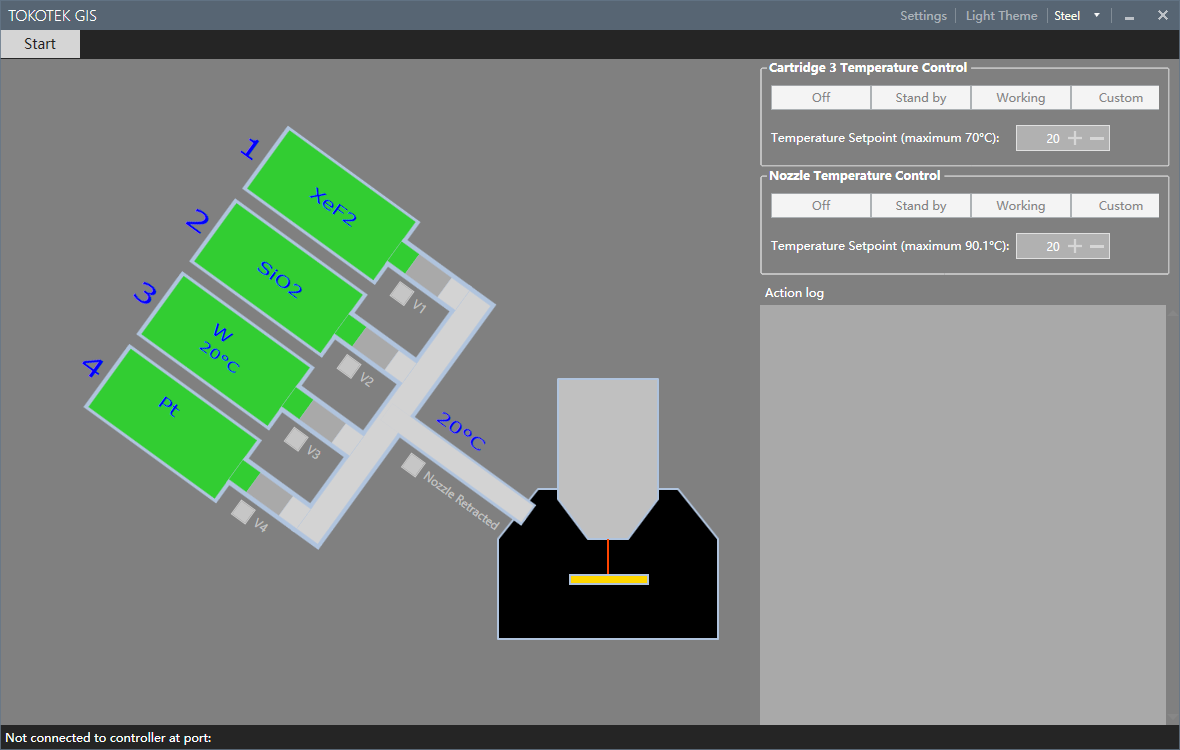

Application Cases

- 产品描述

- 用户界面

- 性能参数

- 应用案例

-

- Commodity name: Micro-Gas injection system Dalex-100

The gas injection system (GIS) is one of the basic configurations of FIB-SEM. It plays two very important roles in FIB-SEM, one is the material deposition function, and the other is the auxiliary etching function. The Dalex-100 gas injection system provides Pt, W and C for deposition protection during cross-section and TEM sample preparation, Pt, W and SiO<sub>2</sub> for circuit repair, and to improve Si cutting Rate of XeF<sub>2</sub>. In addition, it can provide other special precursor gases for milling or gas dry etching of certain materials.

CORE ADVANTAGES:

- Compact design, small size, compatible with various scanning electron microscopes/ focused ion beam microscopes.

- Micro-fine needle can accurately deliver precursor gas to the target processing position.

- Can be equipped with three different types of gas sources, such as metal (tungsten, platinum), insulator (silicon oxide) and etching gas (xenon fluoride).

- Working pressure range can be adjusted to different vacuum applications.

- Can be configured with nitrogen, oxygen, and other gases for pipeline cleaning to reduce contamination.

- User-friendly interface, easy to maintain.

-

-

MICRO-GAS-INJECTION SYSTEM PERFORMANCE PARAMETERS Inside diameter of nozzle <500μm Maximum extension distance of needle working 25mm Planar movement range of needle ±2mm Repeat positioning accuracy of needle XYZ axis Better than 5μm Pressure range 10-7mbar~10-5mbar Deposition rate Maximum 150nm/min

(depending on gas type and working pressure)

Overall weight 3.2kg -

Tungsten nanowires deposited on the surface of silicon wafer.